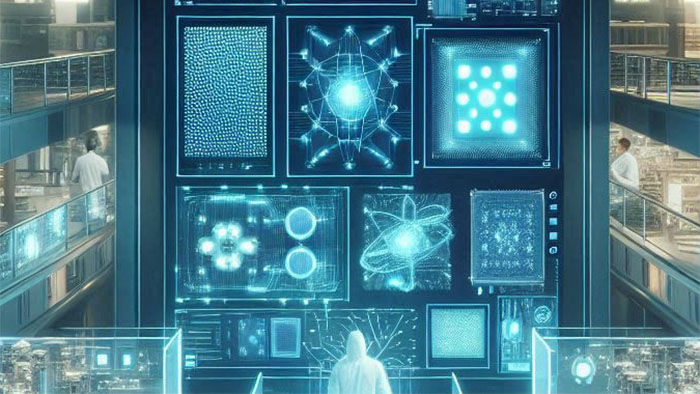

Wafer manufacturing is one of the most fundamental and critical processes in the semiconductor industry. The main steps include:

Silicon Purification: Extract ultra-pure silicon (99.9999%+) from sand to produce polysilicon.

Single Crystal Silicon Growth:

Melt polysilicon using Czochralski method

Dip a seed crystal and rotate/pull to form a single crystal ingot

Common diameters: 150mm(6"), 200mm(8") or 300mm(12")

Ingot Processing:

Trim ends and outer edges

Slice ingot into 0.5-1mm thick wafers using diamond saw

Grind and polish to achieve extremely flat surfaces

Oxidation: Grow silicon dioxide insulating layer through high-temperature oxidation

Photolithography:

Apply photoresist coating

Expose through photomask

Develop to create circuit patterns

Etching: Remove unprotected material using chemical or physical methods

Ion Implantation: Dope silicon with specific ions to form transistor structures

Chemical Vapor Deposition (CVD): Deposit thin films of various materials

Metallization: Create interconnect metal layers

Testing & Packaging: Perform electrical tests, dice into individual chips and package

The entire manufacturing process must be conducted in ultra-clean environments (cleanrooms), may involve hundreds of process steps, and can take several weeks to complete.

Suggested

-

WeChat

-

TEL

13824310467

中文

中文